Why us?

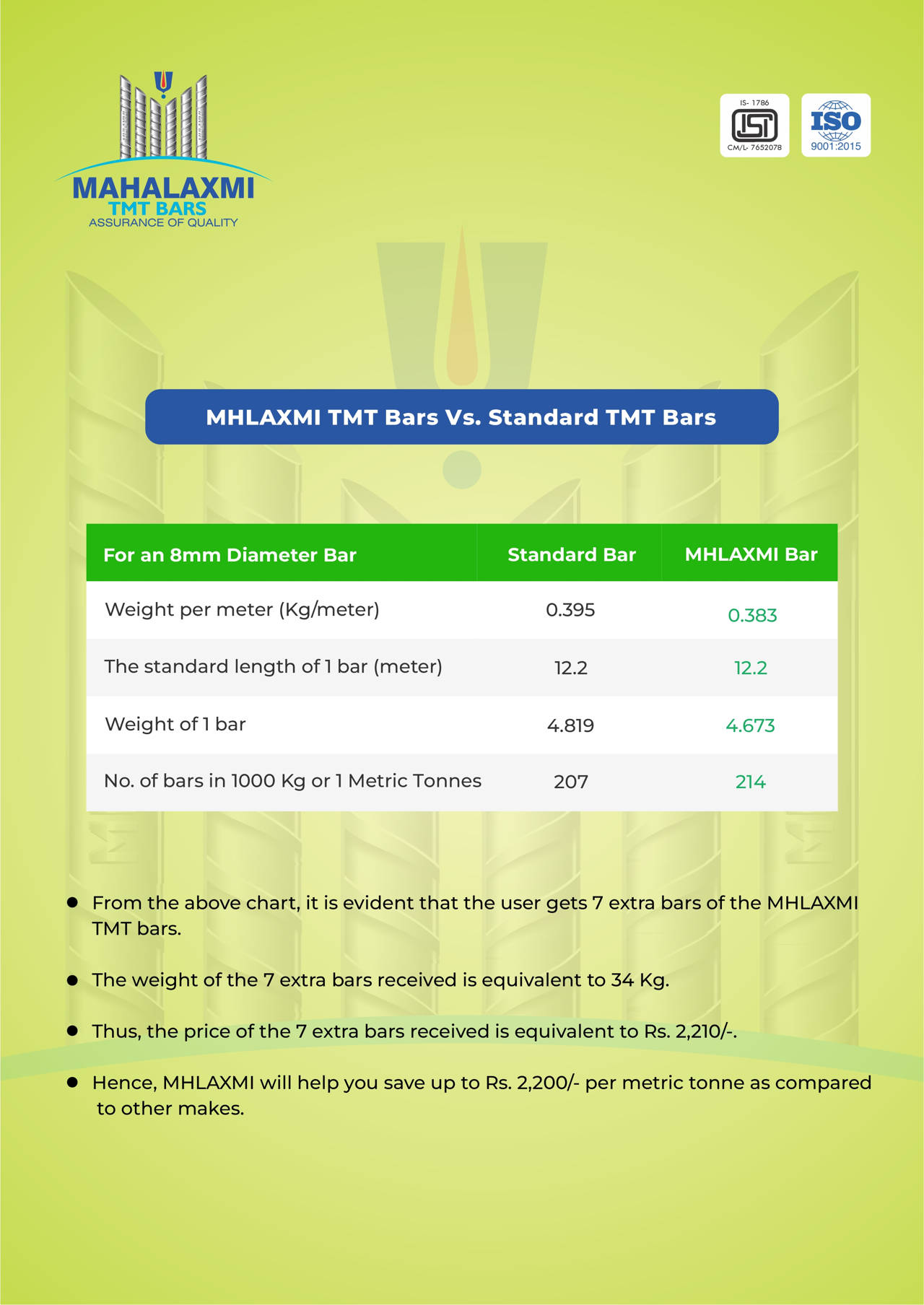

TMT Steel bars, or for that matter, any Reinforcement Bars (Rebars) are used in longer sections for strengthening a structure. Our Mahalaxmi TMT Bars are manufactured to have a Weight-per-meter (WPM) on the negative side of the tolerance range i.e., by -2% of the nominal weight as specified and allowed by the Bureau of Indian Standards. Hence, you get more length of Mahalaxmi bars in the cumulative weight. This saves you Rs. 1400/- Per Metric Ton (PMT) to Rs. 2,200/- PMT.